Part 4: Inspection Process – X-ray & Quinns Comparator

Part 4: Inspection Process – X-ray & Quinns Comparator

At Nortec Solutuions Limited, ensuring the highest quality in electronics manufacturing means going beyond surface-level checks. In Part 4 of our series, we dive into our advanced inspection process that ensures every board meets rigorous standards for reliability and performance.

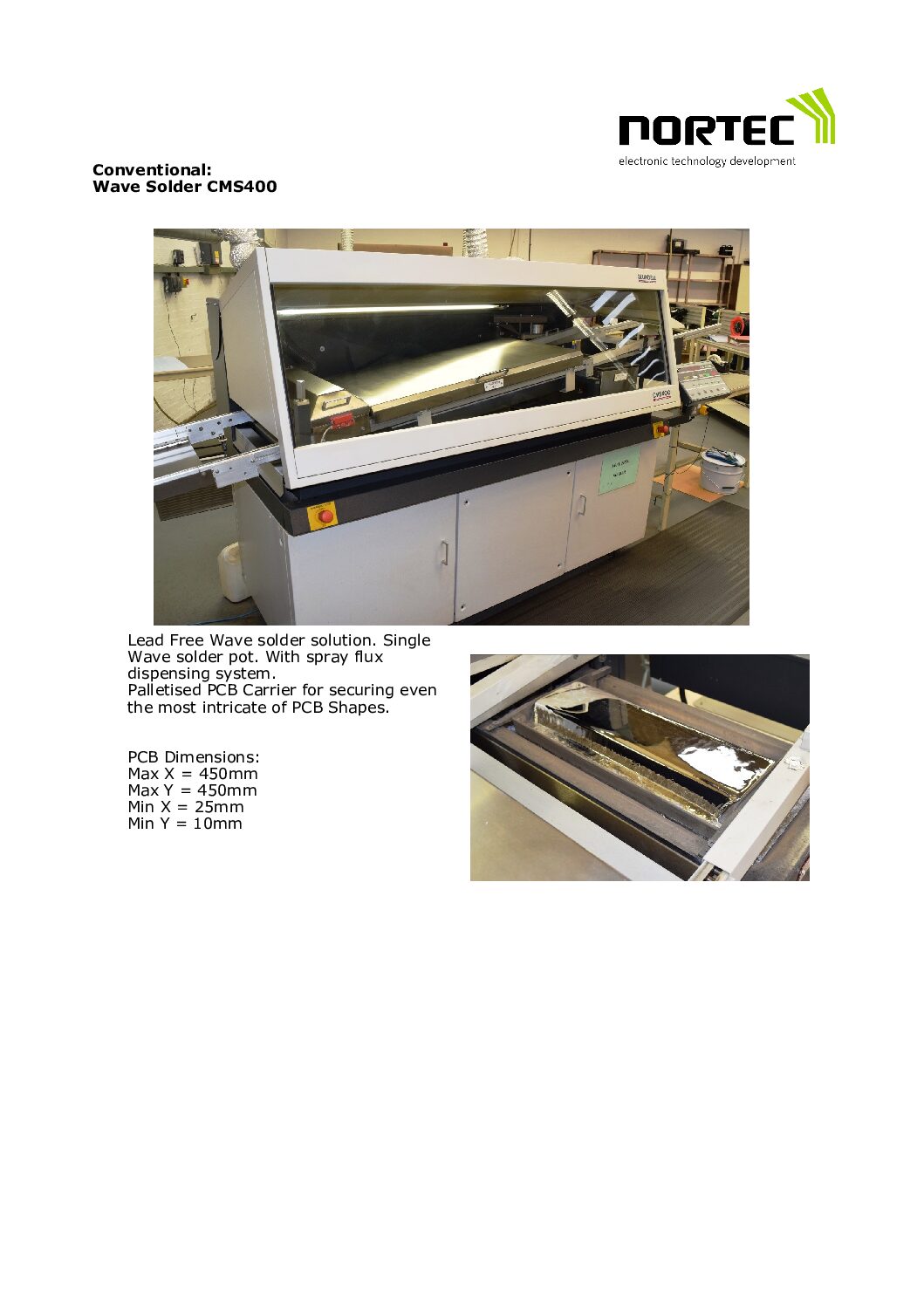

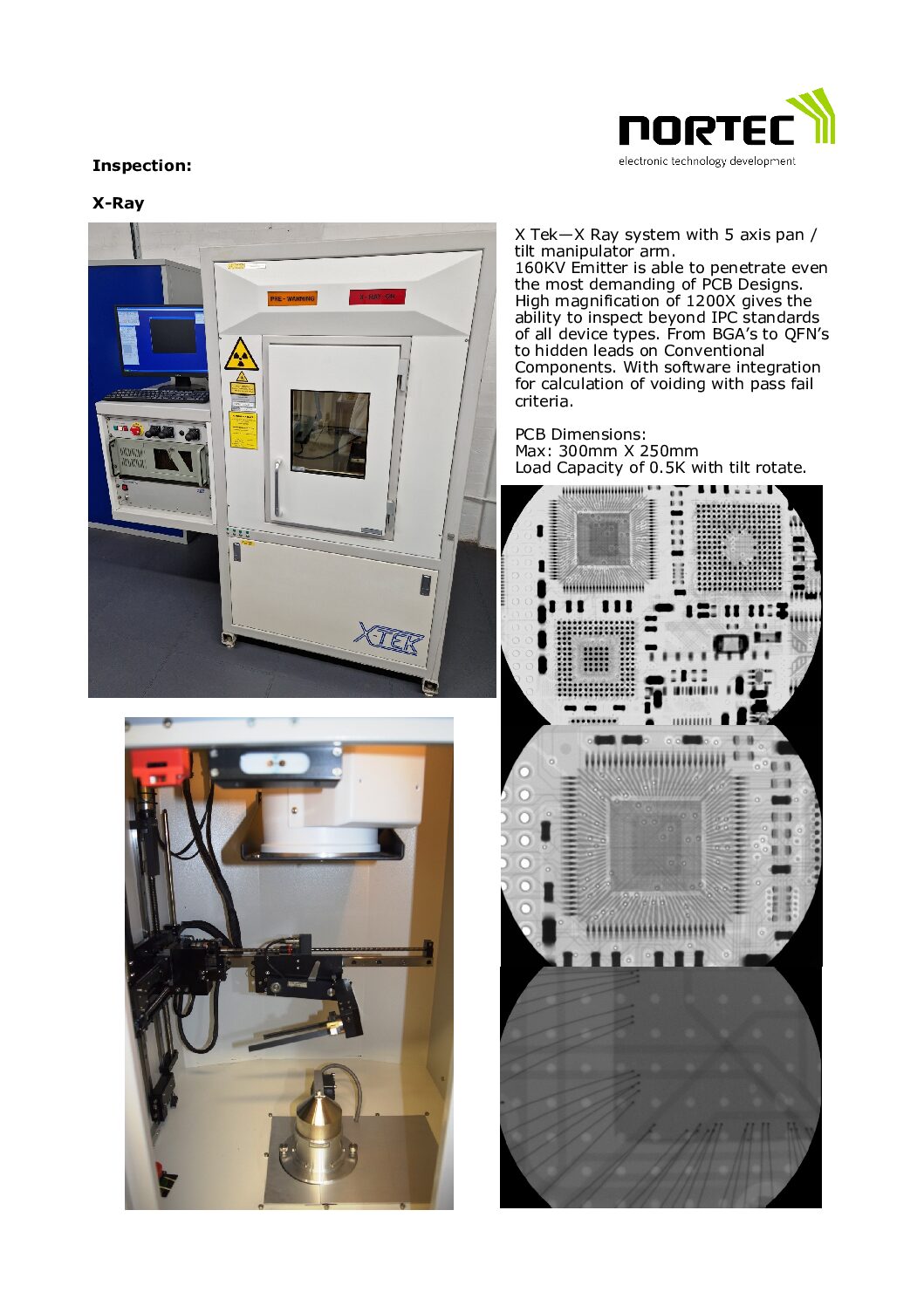

X-Tek E-Xray System (160kV)

Our X-Tek E-Xray System, with its 160kV imaging capabilities, enables non-destructive inspection of even the most densely populated PCBs. It provides high-resolution views of internal layers, solder joints, vias, and BGAs—critical for identifying hidden defects like voids, cold solder joints, or misalignments.

-

Advanced, high-penetration imaging to inspect complex assemblies

-

Perfect for BGAs, QFNs, and multi-layer boards

-

Ensures reliable functionality and compliance with industry standards

Quinns Optical Comparator

For precision visual inspections, our Quinns Optical Comparator comes into play. This tool is essential for verifying component placement, orientation, and marking accuracy—key for ensuring the correct assembly of every board.

-

Visual comparison to master profiles for optimal accuracy

-

Ideal for inspecting fine-pitch components

-

Supports detailed, manual inspection alongside automated processes

Together, these systems form a powerful, multi-layered inspection process that guarantees every PCB is not just visually perfect, but also internally flawless.